Cable joints play a crucial role in maintaining the continuity of electrical cables over long distances by connecting them, allowing the transmission of electricity. These joints must fit precisely and be durable enough to withstand various factors such as adverse weather conditions, current carrying capacity, voltage drop, and material compatibility.

Different types of cable joints exist based on the following factors:

Voltage: The voltage determines whether the cable joints need to be designed for high, medium, or low voltage levels. It is essential for the voltage level of the joint to match that of the cable. If the joint's capacity is lower than that of the cable, it would be inadequate to handle the high current and voltage demands.

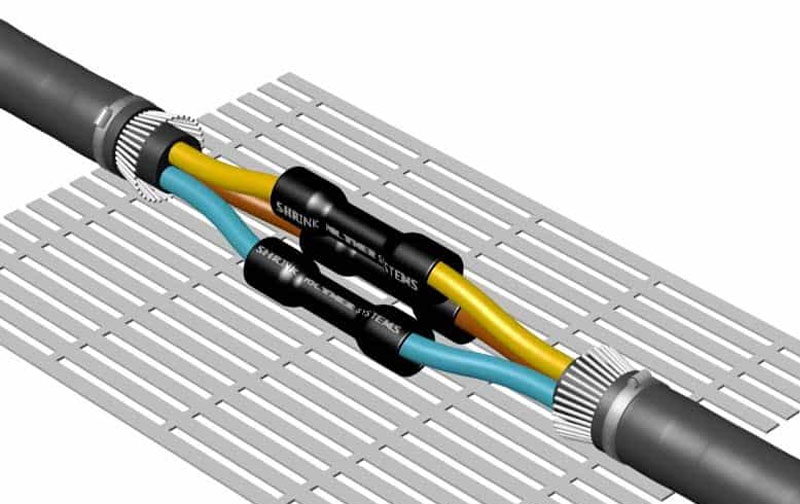

Insulation: For the cable joint to operate properly, the cable's insulation must be compatible with the joint's. Cable joints can be either cold or heat shrinkable, depending on the cable's purpose and insulation type.

Cores: Cables may have single or multiple insulated cores. Cable joints should have the same number of cores as the cables they connect.

Structure: The way in which cables need to be connected determines the type of cable joint to be used. For example, a straight-through joint is used when two cables need to be connected at a single point. If branching is required, appropriate branch cable connectors are utilized. Cable joints can have different structures such as straight-through, T-shaped, Y-shaped, pot-ended, or with indoor or outdoor terminations.

We offer a variety of cable joints, including heat shrinkable cable joints, cold shrinkable cable joints, pre-moulded cable joints, heat shrinkable cable terminations, cold shrinkable cable terminations, pre-moulded cable terminations, and screened separable connectors.

Our range includes armoured and unarmoured heat shrink cable joints for capacities up to 72.5kV. We also provide cold shrink cable straight joints suitable for 1- and 3-core polymeric insulated cables up to 36kV. Additionally, our pre-moulded straight through joints are ideal for polymeric insulated cables up to 36kV.

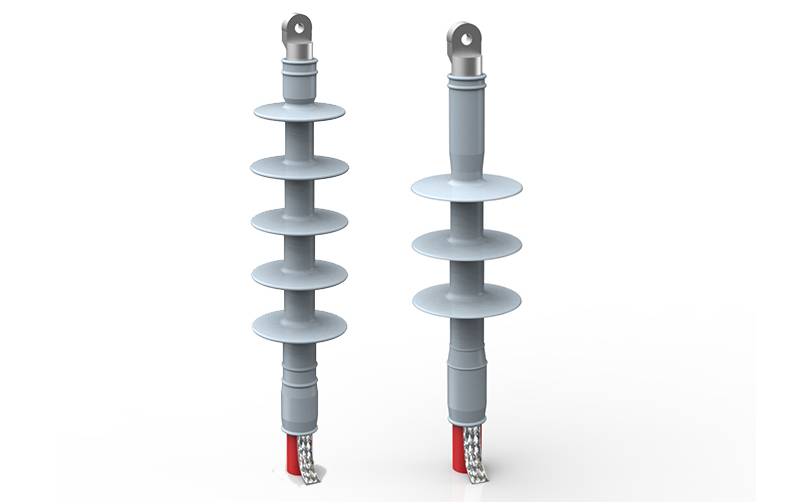

For cable terminations, we offer heat shrink options capable of managing loads from 1kV to 72.5kV. Our cold shrink cable terminations are suitable for 1- and 3-core polymeric insulated cables up to 36kV. Furthermore, our pre-moulded cable terminations (push on/slip-on) are designed for safe use with polymeric insulated cables up to 36kV.

Articles

Why do you need to invest in Lightning Surge Arresters?

Why do you need to invest in Lightning Surge Arresters?

Know the leading Polymer Composite Insulators

Know the leading Polymer Composite Insulators

Clear The Doubts With Essential Data On Cold Shrink Cable Terminations

Clear The Doubts With Essential Data On Cold Shrink Cable Terminations

Top Benefits Of Using The Surge Arrester From The Top Manufacturers

Top Benefits Of Using The Surge Arrester From The Top Manufacturers

Selecting the Appropriate Power Cable Jointing Kits: Essential Factors to Consider

Selecting the Appropriate Power Cable Jointing Kits: Essential Factors to Consider

A cable joint is a point at which two or more electrical cables are joined together. It is necessary to improve the continuous flow of electrical current, repair damaged cables, or lengthen cables. Cable joints provide a secure and dependable connection in a variety of applications, including power distribution and telecommunications.

There are several types of cable joints, including cold shrink joints and heat shrink joints. The choice depends on factors such as the application, cable type, environmental conditions, and voltage requirements. Each type has unique characteristics, installation methods, and advantages, catering to specific needs in different situations.

Choosing the right cable joint requires taking into account factors such as cable type, voltage levels, environmental conditions (e.g., underground, underwater, indoor, or outdoor), and the application's specific requirements. To ensure compatibility and proper installation for optimal performance and safety, consult with experts or follow manufacturer guidelines.

Insulation failure, moisture ingress, and mechanical stress are all common problems. To address these issues, it is critical to use proper installation techniques, high-quality materials, and adhere to manufacturer recommendations. Regular inspections and maintenance also aid in identifying and resolving potential issues before they become major issues, ensuring the longevity and dependability of cable joints.

Yes, cable joints can be installed in hazardous environments; however, careful consideration of safety standards and regulations is required. To reduce the risk of electrical faults or other hazards, precautions may include selecting joints with appropriate certifications for hazardous areas, ensuring proper sealing against moisture and contaminants, and adhering to installation guidelines. When dealing with cable joints in potentially hazardous situations, it is critical to adhere to industry-specific safety standards.

Address 1 - PL214H Al Hamra Industrial Zone-NFZ, RAK, United Arab Emirates

Address 2 - P.O. Box 14577 Warehouse #1, Shed #9

Technology Park, Ras Al Khaimah, U.A.E.

Email : grace@alyamunadensons.ae

Phone : +971 7 2233013

Mobile : +971 542479518

Kindly provide your information, and our expert team will get in touch with you shortly.