Introduction:

In the fast-paced digital age we live in, where connectivity is paramount, cable joints play a crucial role in ensuring seamless transmission of data, power, and signals. These often overlooked components serve as the lifelines of our modern infrastructure, enabling efficient communication networks, robust power transmission, and effective control systems. In this article, we delve into the world of cable joints, examining their importance, types, installation processes, and the key factors to consider for achieving reliable and long-lasting connections.

Understanding Cable Joints:

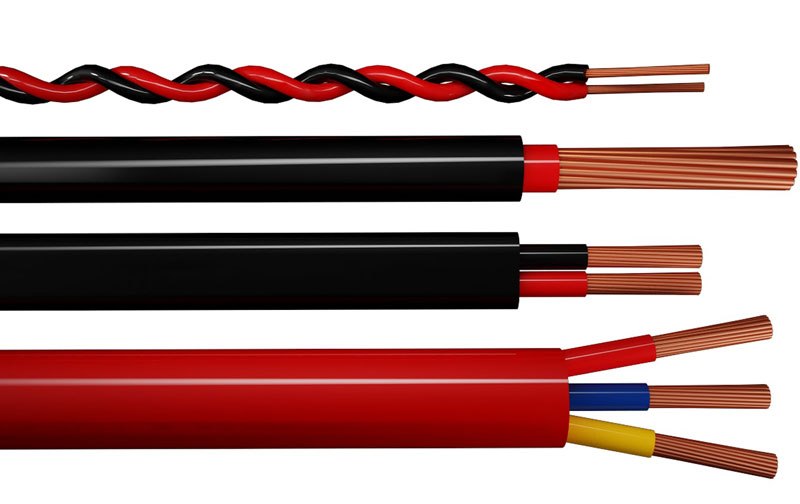

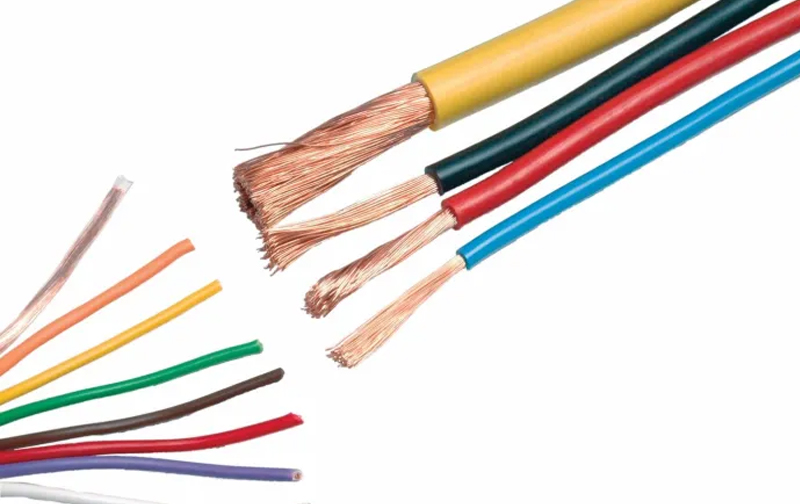

Cable joints, also referred to as connectors or splices, are essential components used to connect or repair cables. They are employed when cables need to be extended, repaired, or branched out. By effectively joining cables, they facilitate the uninterrupted flow of electricity, data, or signals, ensuring the smooth operation of numerous systems and networks.

Types of Cable Joints:

a) Mechanical Cable Joints: These joints utilize mechanical connectors such as clamps, screws, or compression fittings to create a secure connection. They are commonly used in power transmission applications, where high voltage and current levels are involved. Mechanical joints provide excellent mechanical strength and are often resistant to environmental factors such as moisture, heat, and vibrations.

b) Cold Shrink Cable Joints: This type of joint involves a pre-expanded rubber sleeve that is placed over the cable ends. When the outer covering is removed, the rubber sleeve contracts and tightly fits around the cable, forming a reliable seal. Cold shrink cable joints are known for their ease of installation, flexibility, and resistance to moisture and environmental contaminants.

c) Heat Shrink Cable Joints: Heat shrink joints involve the use of a heat-shrinkable tube that is applied to the cable joint. Upon heating, the tube shrinks, creating a tight and secure connection. Heat shrink cable joints provide excellent electrical insulation, mechanical protection, and are widely used in various industries due to their reliability and cost-effectiveness.

Installation Process:

Proper installation of cable joints is crucial to ensuring optimal performance and longevity. It involves several key steps, including cable preparation, connector assembly, insulation and sealing, and stress control. Following manufacturer guidelines, industry standards, and utilizing specialized tools are essential to achieving high-quality and durable cable joints.

Factors for Reliable Cable Joints:

a) Material Selection: Choosing the right materials, such as insulating materials and connector metals, is vital for ensuring compatibility, durability, and resistance to environmental conditions.

b) Proper Insulation: Adequate insulation is crucial to prevent electrical leakage, protect against moisture, and maintain the integrity of the joint.

c) Stress Control: Managing stress and strain on the cable joint is important to prevent mechanical failure and maintain the desired performance level.

d) Testing and Maintenance: Regular testing and maintenance procedures should be implemented to identify any potential issues or deterioration in the joint's performance. This helps ensure early detection and timely repairs, avoiding costly downtime or failures.

Conclusion:

Cable joints may seem like small components, but they play a significant role in maintaining the efficiency, reliability, and safety of our interconnected world. By understanding the different types of cable joints, following proper installation procedures, and considering key factors for reliable connections, we can harness the full potential of our communication networks, power systems, and control mechanisms. Let us embrace the art of cable joints, strengthening the backbone of our technological advancements and embracing a future of seamless connectivity.

Articles

Why do you need to invest in Lightning Surge Arresters?

Why do you need to invest in Lightning Surge Arresters?

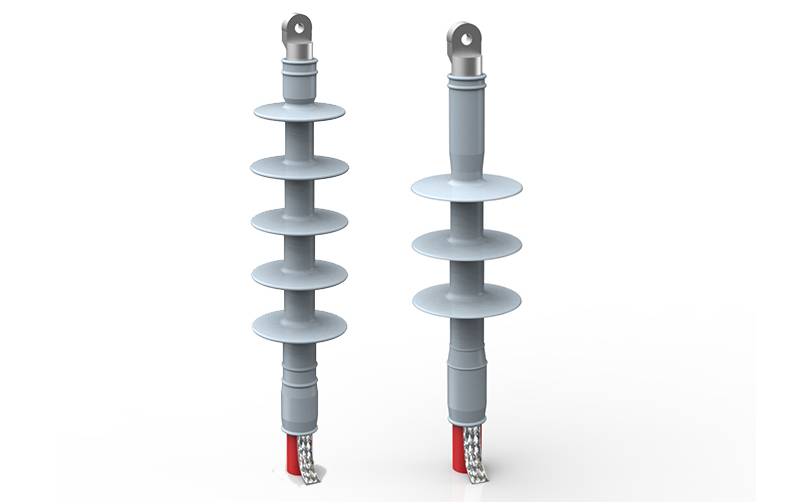

Know the leading Polymer Composite Insulators

Know the leading Polymer Composite Insulators

Clear The Doubts With Essential Data On Cold Shrink Cable Terminations

Clear The Doubts With Essential Data On Cold Shrink Cable Terminations

Top Benefits Of Using The Surge Arrester From The Top Manufacturers

Top Benefits Of Using The Surge Arrester From The Top Manufacturers

Selecting the Appropriate Power Cable Jointing Kits: Essential Factors to Consider

Selecting the Appropriate Power Cable Jointing Kits: Essential Factors to Consider

Address 1 - PL214H Al Hamra Industrial Zone-NFZ, RAK, United Arab Emirates

Address 2 - P.O. Box 14577 Warehouse #1, Shed #9

Technology Park, Ras Al Khaimah, U.A.E.

Email : grace@alyamunadensons.ae

Phone : +971 7 2233013

Mobile : +971 542479518

Kindly provide your information, and our expert team will get in touch with you shortly.