In the intricate world of electrical engineering, the efficiency and reliability of a system often hinge on the quality and appropriateness of its components. Among these critical components, Electrical Elbow Connectors stand out as essential elements that facilitate seamless electrical connections. This comprehensive guide aims to provide an in-depth overview of Electrical Elbow Connectors, covering key aspects, applications, and the crucial role played by Elbow Connectors Suppliers in ensuring optimal performance.

Anatomy of Electrical Elbow Connectors:

Electrical elbow connectors are specialized components designed to facilitate changes in the direction of electrical conductors, offering flexibility and adaptability in various applications. Understanding the anatomy of these connectors, including materials, design features, and construction, is fundamental to their effective use.

Types of Electrical Elbow Connectors:

There is a diverse range of electrical elbow connectors tailored to specific needs. From standard connectors to those designed for high-voltage applications, each type serves a unique purpose. This section will explore the various types, highlighting their characteristics and ideal use cases.

Industrial Applications:

Electrical elbow connectors find widespread use in industrial settings where complex electrical systems require reliable and flexible connections. Their ability to adapt to changing spatial requirements makes them indispensable in manufacturing, automation, and other industrial processes.

Utility and Power Distribution:

In the realm of power distribution and utilities, these connectors play a crucial role in ensuring efficient transmission and distribution of electricity. Their use in power substations and grid systems contributes to the reliability of the electrical infrastructure.

Aerospace and Automotive:

The aerospace and automotive industries demand connectors that can withstand extreme conditions. Electrical elbow connectors, designed for durability and flexibility, find application in aircraft, spacecraft, and vehicles, providing reliable electrical connections in demanding environments.

Considerations for Selection:

Selecting the appropriate electrical elbow connectors involves a careful evaluation of factors such as voltage requirements, environmental conditions, and space constraints. This section will guide readers through the considerations that influence the selection process.

Importance of Quality:

Quality is paramount when it comes to electrical components. Substandard connectors can compromise the performance and safety of an electrical system. Elbow connectors suppliers play a critical role in ensuring that the components meet industry standards and specifications.

Collaborative Partnerships:

Elbow connectors suppliers collaborate closely with manufacturers to provide high-quality components that meet the evolving needs of the industry. Their role in fostering collaborative partnerships contributes to the continuous improvement and innovation in electrical elbow connectors.

Industry Trends and Innovations:

Keeping pace with industry trends, elbow connectors suppliers actively contribute to the integration of new technologies into connector design. This ensures that end-users have access to the latest innovations that enhance the performance and reliability of electrical systems.

In conclusion, the world of Electrical Elbow Connectors is vast and dynamic, with applications spanning diverse industries. This ultimate guide has provided a comprehensive overview, from understanding the anatomy and types of connectors to exploring their applications and the critical role played by elbow connectors suppliers. As technology continues to advance, the guide serves as a valuable resource for professionals seeking to optimize their electrical systems through informed decision-making and strategic component selection.

Articles

Why do you need to invest in Lightning Surge Arresters?

Why do you need to invest in Lightning Surge Arresters?

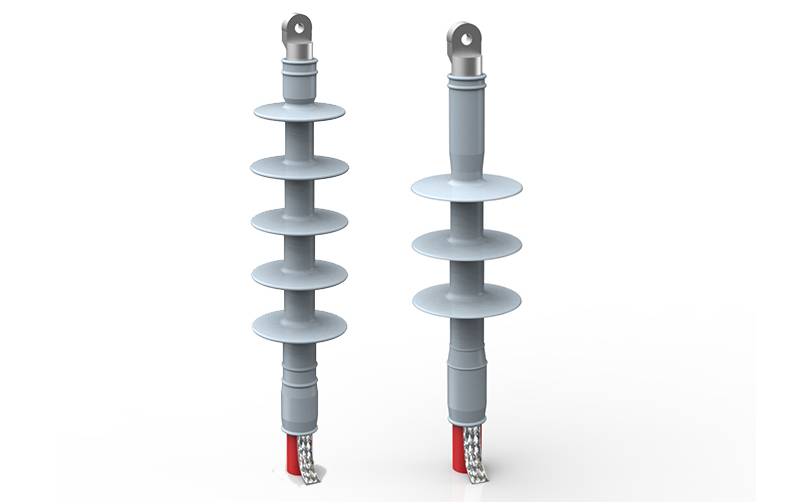

Know the leading Polymer Composite Insulators

Know the leading Polymer Composite Insulators

Clear The Doubts With Essential Data On Cold Shrink Cable Terminations

Clear The Doubts With Essential Data On Cold Shrink Cable Terminations

Top Benefits Of Using The Surge Arrester From The Top Manufacturers

Top Benefits Of Using The Surge Arrester From The Top Manufacturers

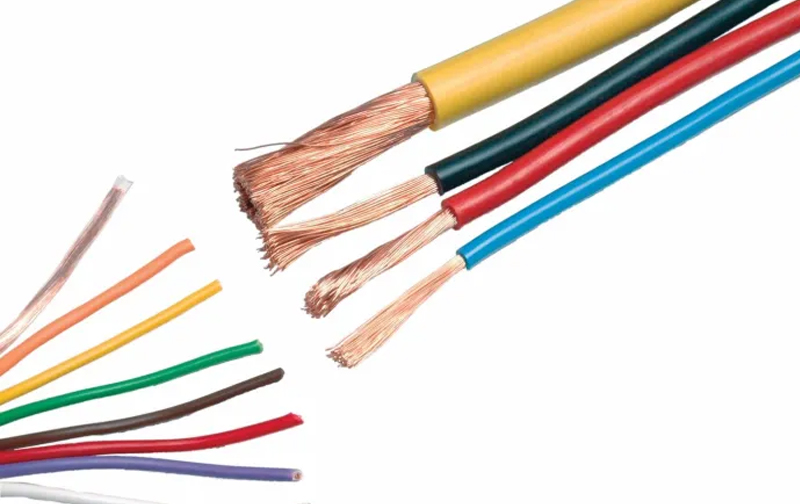

Selecting the Appropriate Power Cable Jointing Kits: Essential Factors to Consider

Selecting the Appropriate Power Cable Jointing Kits: Essential Factors to Consider

Address 1 - PL214H Al Hamra Industrial Zone-NFZ, RAK, United Arab Emirates

Address 2 - P.O. Box 14577 Warehouse #1, Shed #9

Technology Park, Ras Al Khaimah, U.A.E.

Email : grace@alyamunadensons.ae

Phone : +971 7 2233013

Mobile : +971 542479518

Kindly provide your information, and our expert team will get in touch with you shortly.