Introduction

In today’s world, where uninterrupted electricity is the backbone of modern civilization, the significance of every component in the power distribution system cannot be overstated. Among these, cable joints connectors often go unnoticed, yet they are critical in enhancing overall power transmission efficiency. From residential buildings to massive industrial zones, cable joints ensure a smooth and reliable electrical flow. This article explores how these vital components enhance energy efficiency, improve safety, and reduce system losses in power distribution networks.

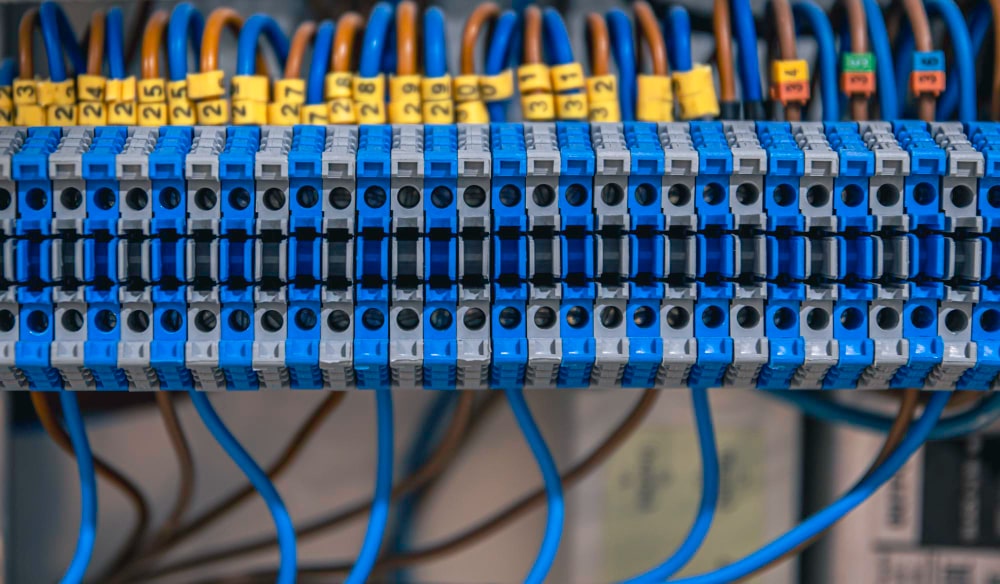

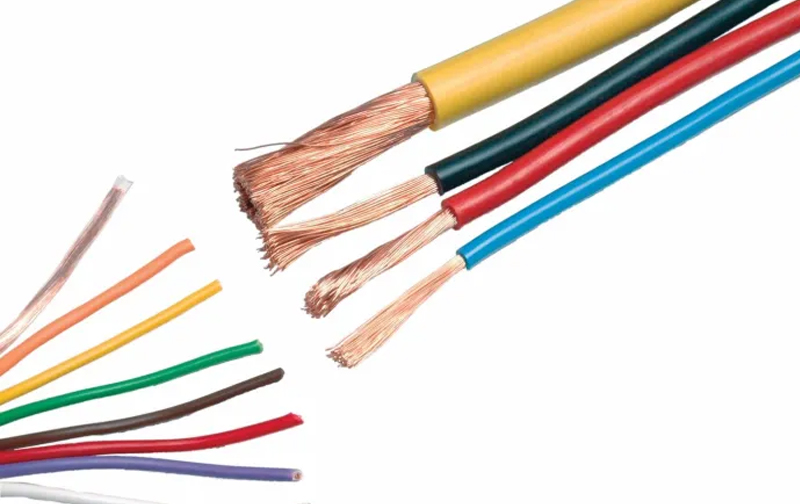

Cable joints connectors are devices used to securely connect two or more lengths of electrical cable, creating a continuous and conductive path for electricity to travel. These joints are essential in large-scale power systems where cables cannot run in one unbroken length. Beyond simply connecting wires, these components are engineered to withstand environmental pressures, electrical loads, and mechanical stress.

There are various types of cable joints available—heat shrink joints, cold shrink joints, resin cast joints, and pre-molded joints—each suited to specific installation needs and voltage capacities. In essence, they act as the invisible links that hold the power infrastructure together. Without efficient joints, cable runs would be shorter, fault-prone, and highly inefficient.

One of the key indicators of power distribution efficiency is how much energy is lost during transmission. A common point of energy loss in electrical systems is where two cables meet. Poor-quality or improperly installed joints can increase resistance, leading to excessive heat build-up, power dissipation, and even fire risks.

High-grade cable joint connectors, however, are specifically designed to offer minimal contact resistance. They provide a secure, tight electrical bond that allows electricity to pass with negligible loss. These joints are often made of copper or aluminum sleeves with conductive greases that enhance electrical continuity while preventing oxidation. With these high-performance connectors, energy efficiency is maximized, and system performance is significantly enhanced, especially in long-distance or high-load transmission systems.

Reliability is crucial in power distribution, especially in industries and services where downtime can result in financial loss, data corruption, or safety hazards. Cable joints connectors contribute to this reliability by maintaining strong mechanical integrity and insulation throughout the cable network.

A well-installed joint prevents issues such as voltage drops, arcing, or insulation failure, ensuring uninterrupted power supply. In large-scale infrastructure such as railway systems, airports, hospitals, and data centers, even a brief interruption in power could be disastrous. Hence, using certified, durable cable joints helps maintain round-the-clock reliability, supporting both infrastructure and end-user satisfaction.

Outdoor and underground power distribution systems are often subjected to extreme environmental conditions such as humidity, rain, temperature fluctuations, UV radiation, and chemical exposure. Cable joints connectors that are not properly sealed can absorb moisture or contaminants, which can lead to dielectric failure, corrosion, and eventual system breakdown.

Modern cable joints are designed with advanced sealing technologies, such as thermoplastic covers, gel-filled tubes, or epoxy resins that offer long-term protection against water ingress and environmental pollutants. This robust protection ensures cable longevity and reduces the risk of electrical faults caused by external environmental factors. In coastal areas or industrial zones where pollution is high, these weatherproof joints are particularly beneficial.

Different applications demand different voltage ratings, and one of the strengths of modern cable joint technology is its adaptability across low, medium, and high voltage systems. For instance, residential networks may operate below 1kV, while industrial or transmission systems may handle voltages above 33kV.

Cable joint connectors are carefully engineered to handle the dielectric and mechanical stresses of these different voltage levels. High-voltage joints include stress control components and specialized insulation to manage electrical fields safely. Low-voltage joints may focus more on flexibility and ease of installation. Regardless of the application, having the right connector for the job ensures safety, performance, and longevity.

As the global power infrastructure evolves into smart grid systems, integrating renewable energy sources and digital monitoring technologies, cable joints connectors are also evolving. In smart grids, where real-time monitoring, bidirectional power flow, and distributed energy resources are involved, joints must offer both performance and compatibility.

Modern joints are being designed with materials and construction that minimize electromagnetic interference (EMI) and allow integration with sensors or remote diagnostic tools. This means power companies can monitor joint health, temperature, and performance remotely, reducing manual inspection needs and improving predictive maintenance capabilities. In essence, cable joints are transitioning from passive components to smart connectors that actively support efficient energy management.

One of the hidden advantages of using high-quality cable joint connectors is that they simplify future maintenance. When a fault occurs in a distribution line, modular and accessible joints allow technicians to isolate the problem area quickly. In contrast, poor or outdated joints often require full cable replacement or excavation, leading to extended outages.

Many cable joint systems today come with color-coded components, integrated stress control, and snap-fit designs that make installation and inspection easier. This reduces human error during installation and ensures faster repair cycles. By minimizing downtime, organizations not only reduce operational disruptions but also save on manpower and maintenance costs.

Electrical accidents can result in injuries, equipment damage, or even fatalities. Faulty or poorly insulated cable joints are one of the most common causes of short circuits, electrocution risks, and cable fires. Safety is, therefore, a non-negotiable feature in power systems.

Modern cable joints are rigorously tested to meet international safety standards. They are equipped with flame-retardant materials, moisture-resistant seals, and thermal stability to ensure they remain safe under varying loads and harsh conditions. These features help prevent leakage currents, over-heating, and dangerous flashovers, making them indispensable in critical applications where safety is paramount.

While investing in high-end cable joints may seem expensive initially, their long-term benefits far outweigh the costs. With lower maintenance needs, reduced energy loss, and fewer replacements, high-quality joints contribute to the overall cost-effectiveness of the power system. Additionally, energy-efficient joints support sustainability by reducing carbon emissions associated with power loss.

In large-scale projects like metro rail systems, energy plants, and smart cities, where cable lengths stretch for kilometers, even a 1% increase in efficiency can lead to substantial energy savings. Therefore, investing in the right cable joints becomes a strategic decision for both financial and environmental reasons.

In conclusion, cable joints connectors are more than just connecting elements—they are essential components that enhance power distribution efficiency, system safety, and grid reliability. Their role in reducing energy losses, resisting environmental stress, and enabling quick maintenance makes them indispensable in both traditional and smart power infrastructure. By investing in the right cable joints and ensuring expert installation, we take a big step toward building a resilient, efficient, and future-ready power network.

Articles

Why do you need to invest in Lightning Surge Arresters?

Why do you need to invest in Lightning Surge Arresters?

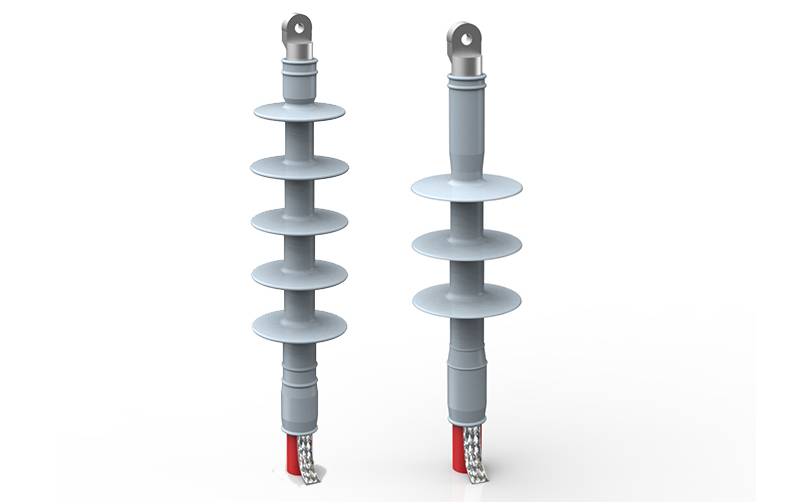

Know the leading Polymer Composite Insulators

Know the leading Polymer Composite Insulators

Clear The Doubts With Essential Data On Cold Shrink Cable Terminations

Clear The Doubts With Essential Data On Cold Shrink Cable Terminations

Top Benefits Of Using The Surge Arrester From The Top Manufacturers

Top Benefits Of Using The Surge Arrester From The Top Manufacturers

Selecting the Appropriate Power Cable Jointing Kits: Essential Factors to Consider

Selecting the Appropriate Power Cable Jointing Kits: Essential Factors to Consider

Address 1 - PL214H Al Hamra Industrial Zone-NFZ, RAK, United Arab Emirates

Address 2 - P.O. Box 14577 Warehouse #1, Shed #9

Technology Park, Ras Al Khaimah, U.A.E.

Email : grace@alyamunadensons.ae

Phone : +971 7 2233013

Mobile : +971 542479518

Kindly provide your information, and our expert team will get in touch with you shortly.