PHeat shrink cable joints are essential components in electrical systems, providing secure and insulated connections for power cables. These joints are widely used in various applications, including underground, overhead, and submersible installations, ensuring the continuous flow of electricity with enhanced safety and durability.

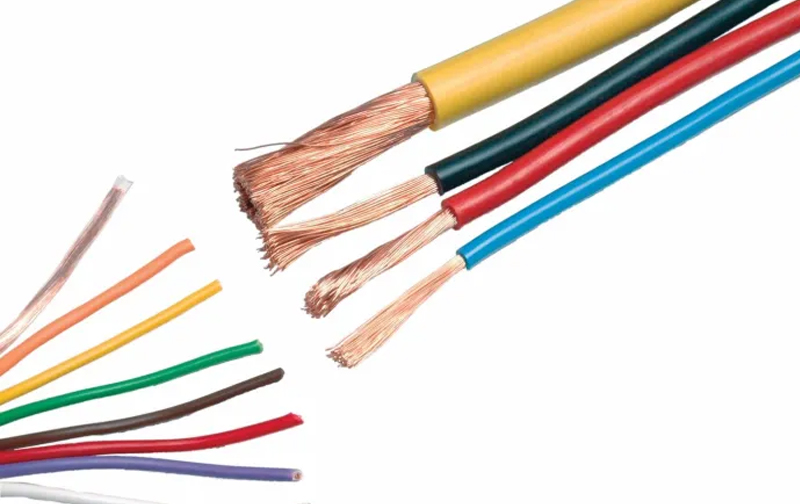

Heat shrink cable joints consist of heat-shrinkable tubes and components that, when heated, shrink to form a tight seal around cable connections. This process offers excellent electrical insulation and mechanical protection, safeguarding the joints against environmental factors such as moisture, dust, and chemicals. The versatility of heat shrink joints makes them suitable for various cable types, including XLPE, PVC, and PILC cables, across different voltage ranges.

Key Features and Benefits

Versatile Applications: Suitable for low, medium, and high voltage cables, accommodating different core configurations and insulation types.

Enhanced Protection: Provides robust insulation and sealing, protecting against environmental contaminants and mechanical stress.

Durability: Manufactured with high-quality materials, these joints offer long-term performance and resistance to aging and corrosion.

Ease of Installation: Designed for straightforward installation, reducing the need for specialized tools and minimizing installation time.

Applications

Heat shrink cable joints are utilized in various sectors, including:

Power Distribution: Connecting cables in substations, transformers, and switchgear.

Industrial Installations: Ensuring reliable connections in manufacturing plants and processing facilities.

Infrastructure Projects: Used in utilities and infrastructure developments for efficient power distribution.

Product Range

The range of heat shrink cable joints includes:

Low Voltage Joints: Designed for 1.1 kV PVC/XLPE/PILC cables, suitable for various core configurations.

Medium Voltage Joints: Suitable for up to 36 kV cables, including 3-core XLPE/EPR insulated cables.

High Voltage Joints: Engineered for up to 72.5 kV single-core XLPE/EPR insulated cables, providing robust performance in demanding environments.

These joints are manufactured in compliance with international standards, ensuring quality and reliability in various applications.

Articles

Why do you need to invest in Lightning Surge Arresters?

Why do you need to invest in Lightning Surge Arresters?

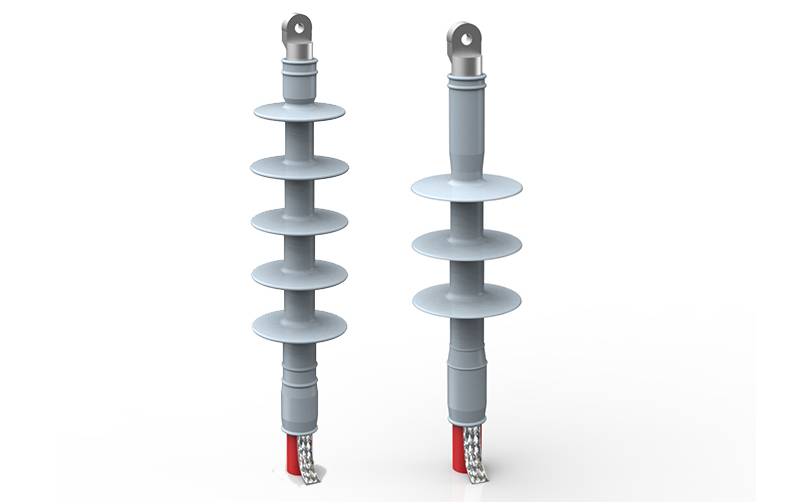

Know the leading Polymer Composite Insulators

Know the leading Polymer Composite Insulators

Clear The Doubts With Essential Data On Cold Shrink Cable Terminations

Clear The Doubts With Essential Data On Cold Shrink Cable Terminations

Top Benefits Of Using The Surge Arrester From The Top Manufacturers

Top Benefits Of Using The Surge Arrester From The Top Manufacturers

Selecting the Appropriate Power Cable Jointing Kits: Essential Factors to Consider

Selecting the Appropriate Power Cable Jointing Kits: Essential Factors to Consider

Heat shrink cable joints are used to connect and insulate power cables, ensuring a secure and protected electrical connection in various installations.

They are compatible with XLPE, PVC, and PILC cables across different voltage levels and core configurations.

Yes, they are designed to withstand environmental factors, making them suitable for outdoor, underground, and submersible applications.

Installation involves preparing the cable ends, applying the heat shrink components, and using heat to shrink the materials, forming a tight and secure seal.

They are manufactured in compliance with international standards, ensuring quality and reliability in various applications.

Address 1 - PL214H Al Hamra Industrial Zone-NFZ, RAK, United Arab Emirates

Address 2 - P.O. Box 14577 Warehouse #1, Shed #9

Technology Park, Ras Al Khaimah, U.A.E.

Email : grace@alyamunadensons.ae

Phone : +971 7 2233013

Mobile : +971 542479518

Kindly provide your information, and our expert team will get in touch with you shortly.