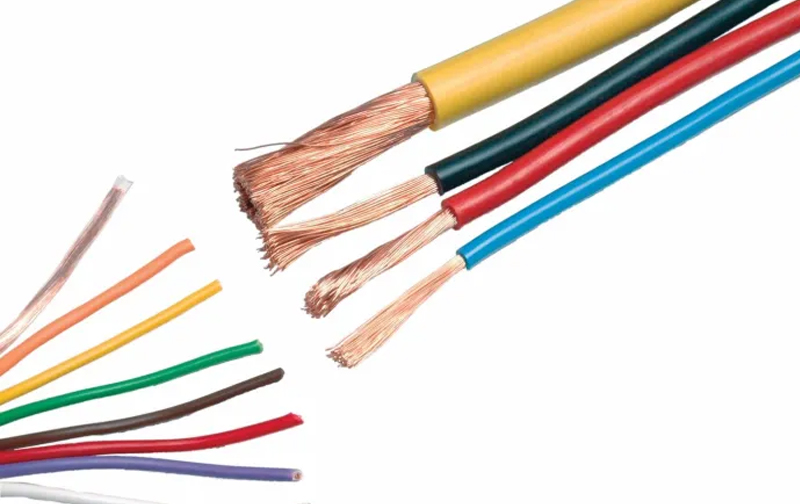

Wire insulation forms a crucial outer layer. The insulation gets applied to wires and electrical cables, safeguarding the wires from harsh external conditions. The insulation is a form of jacket that offers dual benefits. It prevents the electrical current from leaking from the cables into the surrounding area and ensures optimal protection. The insulation process is critical to meet the needs of the dynamic challenges and range of wire materials and applications. Thus, wire insulation techniques are available in multiple types and materials.

About the insulators

An Electrical Insulator is a critical aspect of industrial applications. It uses material through which electric current cannot flow. The atoms of an insulator have intensely bound electrons. These cannot readily move, preventing the free flow. The material property distinguishes an insulator and enhances its resistivity. Modern insulators have excellent resistivity compared to semiconductors or conductors.

Functionality and purpose:

The objective of using an insulator is to stop the unwanted free flow of current from a conductor and its parts. The process of electrical insulation plays a significant part in every electrical system. An insulator offers optimal resistance and does not create a loophole in the current flow.

Versatile types:

Electrical insulation could be in various forms. The different insulators are apt for specific applications and conditions. The best choice of insulation type can depend on versatile factors including - voltage levels, temperature, environmental factors, and specific requirements of the system.

Solid insulation and its types:

Solid insulation is a conventional choice, and the process is used in most cases of electrical insulation. The types include –

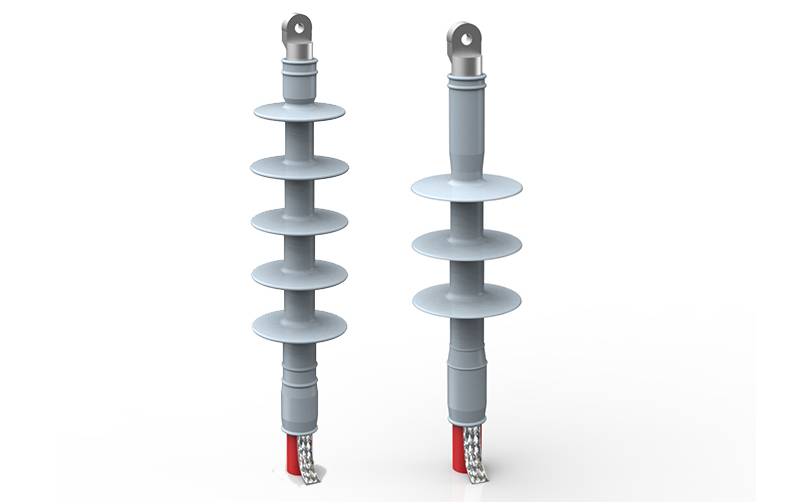

1. Plastic Insulation: Polymer Composite Insulators have materials like polyvinyl chloride (PVC), polyethylene (PE), and cross-linked polyethylene (XLPE). These are excellent for insulating the electrical wires and electrical equipment. They offer impeccable electrical insulation properties, wiring flexibility, and resistance to moisture and chemicals.

2. Rubber Insulation: Ethylene propylene diene monomer and silicone rubber are used for insulation in electrical cables, power cords, and connectors. Rubber insulation ensures wiring flexibility and high resistance to heat, chemicals, and moisture.

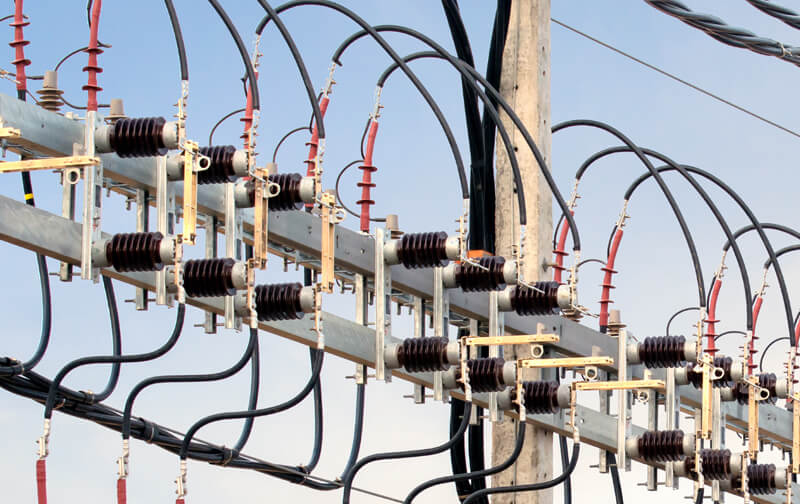

3. Ceramic Insulation: Ceramics like porcelain, alumina, and steatite have impeccable electrical resistance. Hence, these get used in heavy-duty applications that need high-temperature resistance. One can find these insulators in high-voltage power lines and spark plugs.

4. Composite Insulation: Composite insulating materials can contain versatile materials to develop a synergistic effect. It can contain fiberglass-reinforced plastics (FRP) for insulating support structures in heavy-duty and high-voltage equipment. It adds to strength and resistance.

Applications and industrial use: Plastic wire insulation is vital for -

1. Medical applications

2. Food and beverage industry

3. Military applications

4. Industrial power plants

5. Marine and low-temperature environments

6. Power and control cable applications

Closing note

Engineers and Polymeric Insulators Suppliers are experts in the matter, and they offer the best solutions for insulation requirements. Find reliable and secure electrical installations with the top manufacturers by obtaining a clarified overview. Keep the essential pointers in mind if you need to order such items.

Articles

Why do you need to invest in Lightning Surge Arresters?

Why do you need to invest in Lightning Surge Arresters?

Know the leading Polymer Composite Insulators

Know the leading Polymer Composite Insulators

Clear The Doubts With Essential Data On Cold Shrink Cable Terminations

Clear The Doubts With Essential Data On Cold Shrink Cable Terminations

Top Benefits Of Using The Surge Arrester From The Top Manufacturers

Top Benefits Of Using The Surge Arrester From The Top Manufacturers

Selecting the Appropriate Power Cable Jointing Kits: Essential Factors to Consider

Selecting the Appropriate Power Cable Jointing Kits: Essential Factors to Consider

Address 1 - PL214H Al Hamra Industrial Zone-NFZ, RAK, United Arab Emirates

Address 2 - P.O. Box 14577 Warehouse #1, Shed #9

Technology Park, Ras Al Khaimah, U.A.E.

Email : grace@alyamunadensons.ae

Phone : +971 7 2233013

Mobile : +971 542479518

Kindly provide your information, and our expert team will get in touch with you shortly.